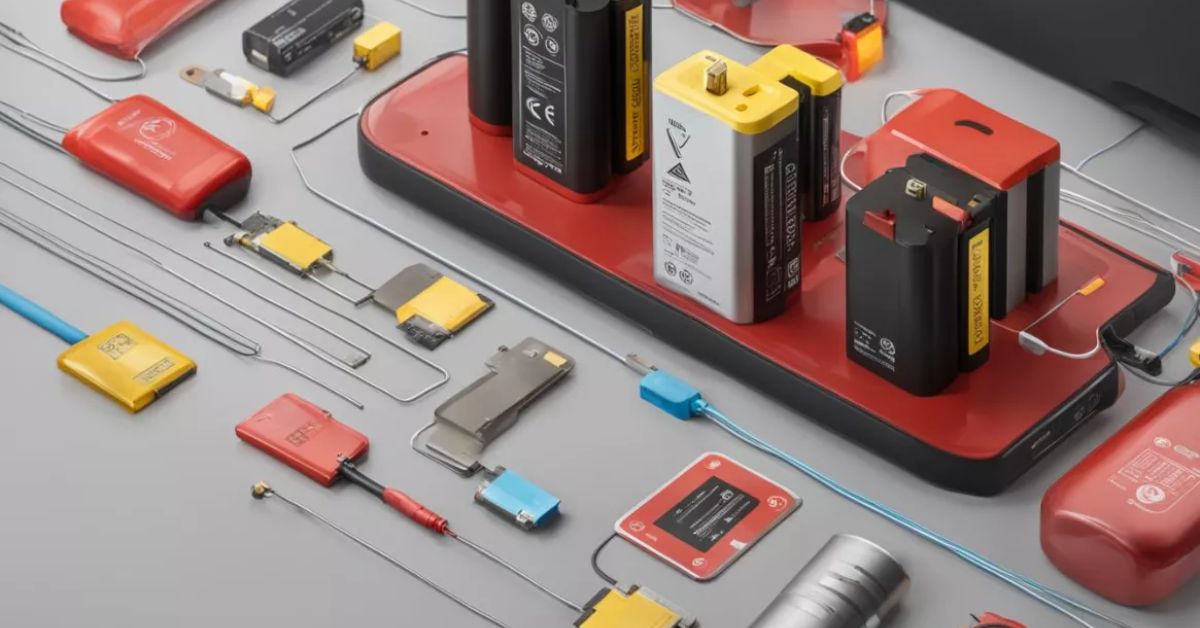

Transporting lithium batteries safely is vital in today’s global economy. With electronic devices relying on these batteries, ensuring they don’t cause harm during transit is more important than ever. The UN38.3 standard is designed to protect both people and goods by ensuring battery safety during shipment.

Companies like Amicell are at the forefront of this effort, adhering to the UN38.3 guidelines to ensure their batteries meet global safety standards. By following these rigorous tests, Amicell guarantees that their products reach customers without risks. Compliance is not just about following rules—it’s about preventing potential hazards.

In this article, we’ll dive deep into the UN38.3 standard and why it’s crucial for battery transport. We’ll explore Amicell’s role in ensuring compliance and how they work to keep their batteries safe during transit.

Also read this blog: Geekzilla Radio: Your Ultimate Source for Geek Culture

What is the UN38.3 Standard?

The UN38.3 standard is an international regulation for testing and transporting lithium-ion batteries. It is part of the United Nations Manual of Tests and Criteria, which outlines a series of safety tests that lithium batteries must undergo to be considered safe for transport.

Lithium-ion batteries are used in numerous devices, from smartphones to electric vehicles. The UN38.3 standard ensures that these batteries are safe to transport without posing a risk of fire, explosion, or other hazards.

Importance of Battery Safety in Global Transport

Battery safety is essential in the global transportation of goods. Lithium batteries, especially, pose risks when mishandled or transported without proper precautions. These batteries can overheat, short-circuit, or even explode if not properly packaged and tested.

Transporting batteries in compliance with UN38.3 reduces these risks significantly. The tests ensure that batteries can withstand mechanical stress, extreme temperatures, and environmental factors. Without adhering to these safety measures, companies could face severe consequences, including accidents, legal issues, and damage to their reputation.

Key Requirements of the UN38.3 Standard

The UN38.3 standard outlines several key requirements for lithium battery testing. These include mechanical shock tests, thermal tests, and vibration assessments. Each of these tests evaluates the battery’s ability to withstand real-world conditions during transport. Batteries must pass these tests to be certified for transportation.

This test checks the battery’s performance in low-pressure environments, such as those experienced during air travel. Meeting these requirements ensures that batteries are safe for shipment across various transportation modes, including air, sea, and land.

Also read this blog: G.G. Ginley: A Comprehensive Overview

The Role of Amicell in Battery Compliance

Amicell is a leading battery manufacturer committed to safety and compliance. They ensure that their batteries meet the strict standards set by UN38.3. This dedication to safety goes beyond just following regulations—Amicell prioritises the well-being of their customers and transport partners.

By partnering with certified testing facilities, Amicell ensures that every battery they produce undergoes thorough testing. Their focus on compliance builds trust with consumers, who can rest assured that Amicell’s products are safe for transport and use.

Testing Procedures Under UN38.3

Testing procedures under the UN38.3 standard are designed to push batteries to their limits. Mechanical shock tests simulate the impacts that batteries may face during transport. Vibration tests ensure that batteries remain stable under the constant shaking of transportation vehicles.

Thermal testing exposes batteries to extreme high and low temperatures to assess how they handle environmental stress. The overcharge test examines how batteries react to being overcharged, ensuring they do not overheat or explode. These rigorous procedures ensure batteries are safe for worldwide shipping.

How Amicell Ensures Battery Safety During Transit

Amicell employs strict safety protocols to ensure their batteries remain secure during transit. They work closely with transport companies to guarantee proper packaging and handling. Amicell’s batteries are tested in real-world conditions, which helps ensure they perform safely under various transport modes.

Additionally, Amicell continuously reviews and updates their battery designs to keep up with advancements in safety standards. This proactive approach helps minimise the risks associated with transporting lithium batteries, providing peace of mind to their customers and logistics partners.

The Impact of Non-Compliance with UN38.3

Non-compliance with UN38.3 can have serious consequences. Companies that fail to meet the standard risk of accidents, product recalls, and legal penalties. Shipping non-compliant batteries increases the risk of fires, explosions, and environmental damage, leading to significant financial losses and harm to the company’s reputation.

Moreover, non-compliant shipments can be seized or denied entry at borders, disrupting the supply chain. For businesses, compliance with UN38.3 is not just about safety—it’s also about maintaining operational efficiency and avoiding costly delays.

Packaging Guidelines for UN38.3 Certified Batteries

Proper packaging is crucial for ensuring that batteries certified under UN38.3 remain safe during transport. The packaging must prevent short circuits and protect the batteries from physical damage. It should also include labels that clearly identify the contents as lithium batteries, along with instructions for safe handling.

Packaging must also comply with the specific regulations for each mode of transport, whether by land, sea, or air. By following these packaging guidelines, companies can reduce the risk of accidents and ensure their products are shipped safely.

Also read this blog: VenturesGet.net: Insights on Business and Tech

Temperature Control and Environmental Stress Testing

Temperature control is an important factor in battery transport. Lithium batteries are sensitive to extreme temperatures, which can cause them to malfunction or even ignite. UN38.3 requires batteries to undergo temperature cycling tests, which simulate exposure to extreme heat and cold to ensure they remain safe under all conditions.

Amicell incorporates these environmental stress tests into their battery manufacturing process. Their batteries are tested in high-heat environments and freezing temperatures, ensuring they maintain stability and safety, regardless of the conditions they face during transportation.

Transport Modes Covered by UN38.3 Standards

UN38.3 covers three major transport modes: ground, air, and sea. Each mode poses unique risks that batteries must be tested for. Ground transportation, for instance, requires batteries to withstand shocks and vibrations. Air transportation requires batteries to remain safe at high altitudes with low pressure.

Sea transportation adds the risk of exposure to saltwater and humidity, which can corrode battery components. UN38.3 ensures that lithium batteries are prepared for each of these conditions, minimising the risks associated with global transport.

How Amicell Addresses Lithium Battery Safety Concerns

Amicell is dedicated to addressing safety concerns associated with lithium batteries. They go beyond basic testing by implementing advanced safety features in their battery designs. These features include thermal management systems that prevent overheating and safety valves that release pressure to avoid explosions.

By constantly innovating and improving their products, Amicell addresses potential safety risks before they become issues. This forward-thinking approach helps protect both their customers and the environment from the dangers posed by lithium batteries.

Regulatory Bodies Governing Battery Transport

Several regulatory bodies oversee the safe transport of lithium batteries. These include the International Air Transport Association (IATA), the International Maritime Organisation (IMO), and the U.S. Department of Transportation (DOT). Each organisation has specific guidelines for transporting lithium batteries, which must be followed to ensure compliance.

Amicell works closely with these regulatory bodies to ensure their batteries meet all necessary requirements. By staying up-to-date on the latest regulations, they ensure their products are safe to transport worldwide.

Amicell’s Collaboration with Logistics Partners

Amicell collaborates with logistics partners to ensure the safe transport of their batteries. They provide clear instructions for packaging and handling and work with shipping companies to ensure that batteries are properly labelled and stored during transit.

By partnering with trusted logistics providers, Amicell minimises the risks associated with shipping lithium batteries. This collaborative approach ensures that their products reach customers safely and efficiently, without compromising on safety standards.

Technological Advancements in Battery Testing and Compliance

The field of battery testing is constantly evolving, and Amicell stays at the forefront of these advancements. They use the latest technology to test their batteries more accurately and efficiently. Innovations like automated testing systems allow Amicell to test large batches of batteries quickly without sacrificing thoroughness.

These technological advancements not only improve safety but also reduce the time it takes to bring new products to market. By investing in cutting-edge testing tools, Amicell ensures their batteries are both safe and compliant with global standards.

The Future of Battery Transport Safety and Amicell’s Ongoing Commitment

As battery technology continues to evolve, so too will the standards for safe transport. Amicell remains committed to staying ahead of these changes by continuously improving their safety protocols and testing procedures. Their goal is to lead the industry in battery safety and compliance, ensuring that their products are always ready for global transport.

Looking ahead, Amicell plans to invest in more advanced safety features and testing technologies. Their ongoing commitment to safety and compliance ensures that they will continue to set the standard for safe battery transport well into the future.

FAQ’S

Is UN38.3 mandatory?

Yes, UN38.3 is mandatory for the transportation of lithium-ion batteries by air, sea, and land. It ensures the safety of batteries during transit, protecting against potential risks like fires or explosions.

How long does UN38.3 take?

The UN38.3 testing process typically takes 2 to 4 weeks, depending on the testing facility and the complexity of the battery. This period includes multiple stages of testing to ensure safety.

What is the difference between MSDS and UN38.3?

MSDS (Material Safety Data Sheet) provides safety and handling information about substances, while UN38.3 focuses specifically on the testing and transport safety requirements of lithium batteries for compliance in global transport.

What is the purpose of UN38.3?

The purpose of UN38.3 is to ensure that lithium batteries can be safely transported. It sets testing standards to prevent hazards like overheating, short-circuits, and explosions during shipment across different transport modes.

Conclusion

The UN38.3 standard is vital for ensuring the safe transportation of lithium batteries across global markets. It mitigates risks such as fire, explosions, and environmental hazards by enforcing rigorous testing and compliance measures. Adhering to these regulations is crucial for protecting both businesses and consumers.

Amicell’s commitment to following UN38.3 guidelines reflects its dedication to safety and reliability. By complying with these international standards, Amicell not only ensures safe battery transport but also builds consumer trust and reduces potential liability risks in the marketplace.

BagisPack.com: Your ultimate travel companion. Explore expert travel tips, packing guides, and destination insights. Empowering adventurers with essential advice for seamless journeys around the globe.